In 2016, we had the incredible opportunity to evaluate the load-bearing capacity of our Treehouse Attachment Bolts (TABs) at the ICC-accredited testing facility at Washington State University (WSU).* There, we conducted a series of directional tests on our Standard Limb (SL) and Heavy Limb (HL) TABs in two different tree species: Doug fir and western red cedar. Made of heavy-duty, heat-treated steel, TABs are the backbone of our science of treehouse-building—we use them in every one of our builds around the world.

The results blew us away, demonstrating that our TABs exceed expectations for how much force they can safely endure.* WSU’s findings underline the strength of our treehouse hardware and will benefit the treehouse-building community for years to come, helping us build the safest, most sustainable treehouses possible.

*Hey! Read this important note: The load that this treehouse hardware can bear depends on many factors, including the species and health of your tree(s). Treehouse maintenance is required every year to ensure the structure, and tree(s) remain safe and secure for years to come, and more importantly that its users are not put at risk. Perform frequent inspections and maintenance. Improperly installed hardware can pose a significant risk to all parties involved. Use hardware at your own risk. Be in a Tree LLC and Nelson Treehouse and Supply disclaim and assume no liability, are not responsible for property damage, personal injury or consequential damages alleged to be the result of use of this product. Click here to read more about disclaimers and limitations. OK thanks! Keep reading for more info on TAB testing…

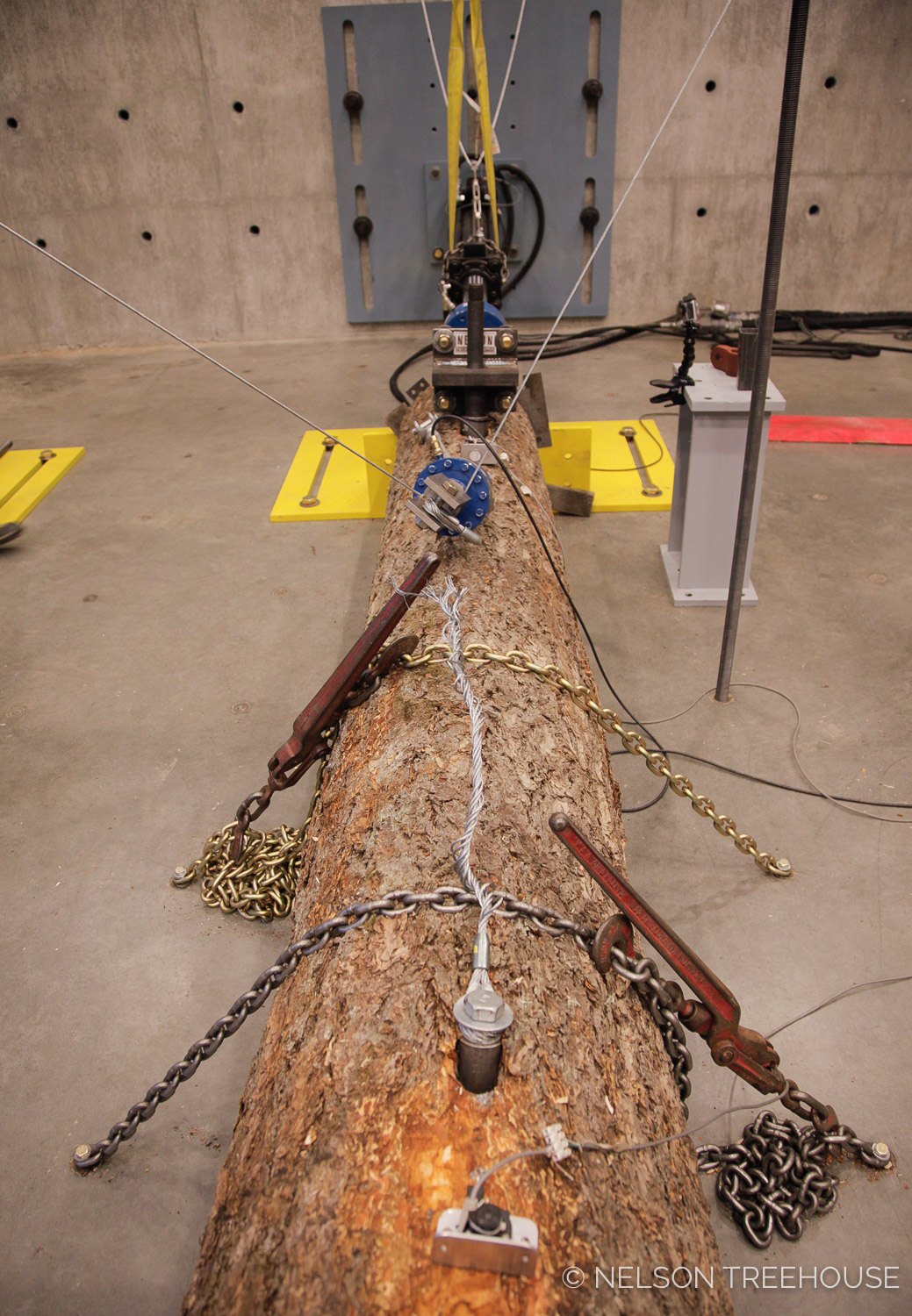

Nelson Treehouse Project Manager Scott Atkins preps a log for TAB testing at the WSU Composite Materials and EnginEering Center.

Nelson Treehouse Project Manager Scott Atkins preps a log for TAB testing at the WSU Composite Materials and EnginEering Center.

With spring around the corner, you might be starting to dream up your next backyard treehouse project. We’re here to equip you with the best information and hardware to help bring your treehouse dreams to life in a safe and sustainable way. We hope that learning about the load-bearing capacity of our TABs informs your DIY treehouse project. You can browse and buy all of our hardware at shop.nelsontreehouse.com.

Inside the Composite Materials and Engineering Center (CMEC) at WSU, testing was conducted on Nelson Treehouse SL and HL TABs with and without a cable backup system. Load was applied to simulate three conditions: gravity load (downward force), wind load (lateral force), and withdrawal from the tree (pull-out). The hardware was tested in freshly sawn Doug fir and western red cedar logs to closely approximate live trees.

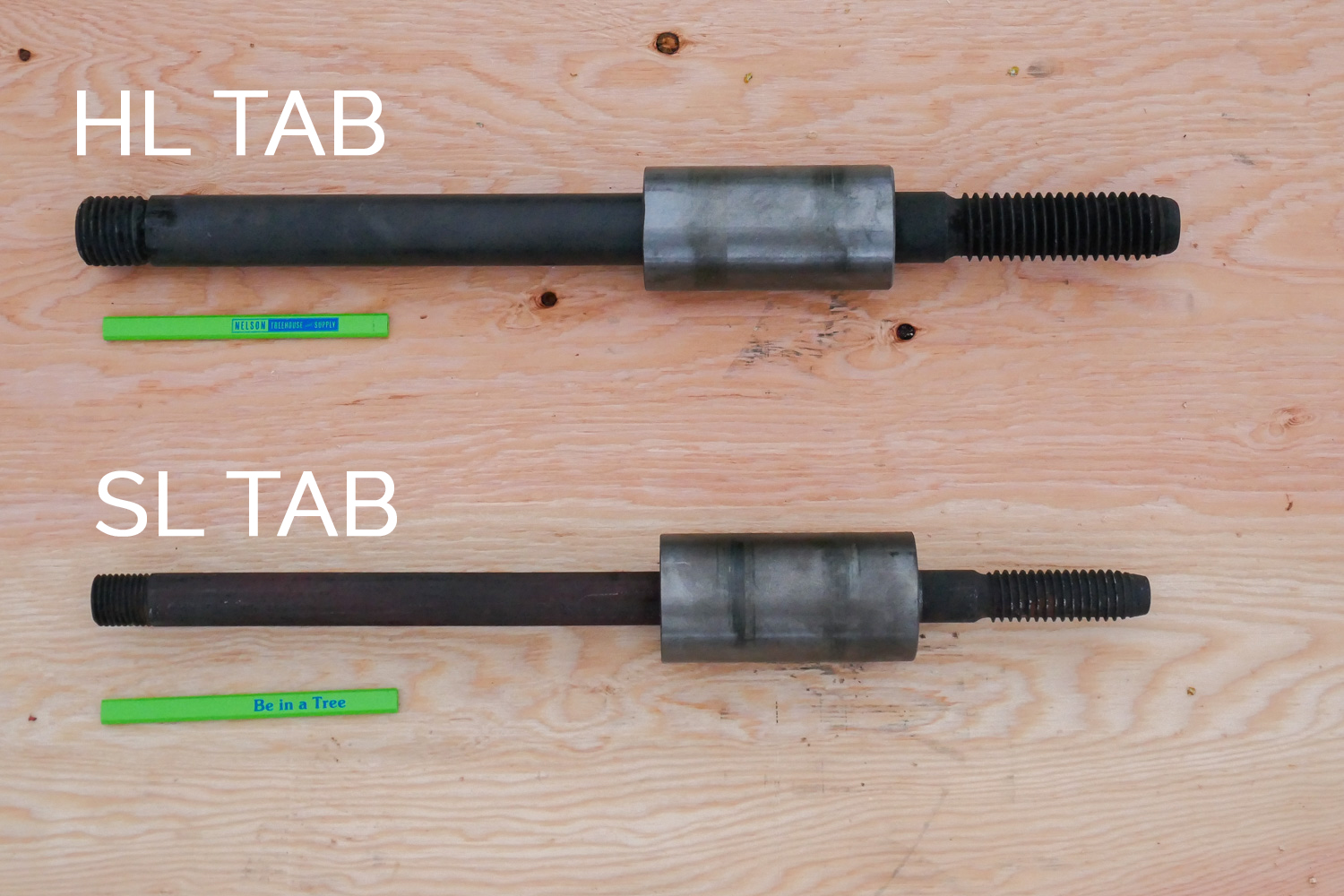

Nelson Treehouse HEavy Limb and Standard Limb Treehouse ATtachment Bolts (TABs).

Nelson Treehouse HEavy Limb and Standard Limb Treehouse ATtachment Bolts (TABs).

Researchers bolted and chained logs to the floor of the lab and set up loading machinery around each. Members of the Nelson Treehouse crew installed TABs into the logs, using the same methods they use on all treehouse builds. As the loading machinery steadily applied force to the TABs, researchers monitored and recorded movement. TABs were tested for their “working load” (day-to-day acceptable load they can bear) and “peak load” (point at which the TAB would fail – typically in the form of bending sharply or pulling out from the log).

Logs were chained to the floor of the CMEC and attached to a loading setup.

Logs were chained to the floor of the CMEC and attached to a loading setup.

TAbs Were monitored for movement while load was applied in each of the tests.

TAbs Were monitored for movement while load was applied in each of the tests.

Each TAB was tested for “Working” and “Peak” Loads – Peak load was marked when the TAB bent at an angle or pulled out from the tree.

Each TAB was tested for “Working” and “Peak” Loads – Peak load was marked when the TAB bent at an angle or pulled out from the tree.

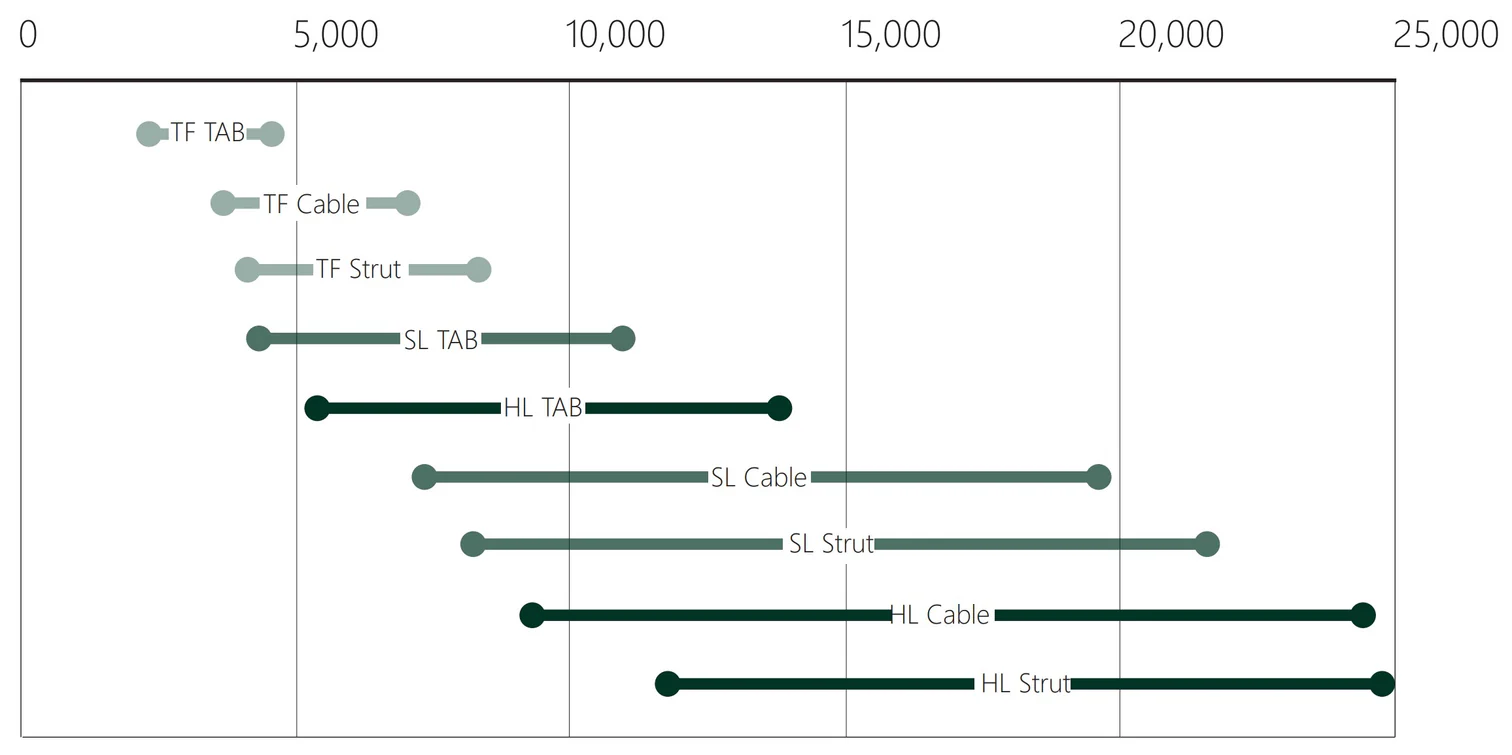

The table below displays gravity test results for working and peak loads for SL and HL TAB configurations in both Doug fir and western red cedar logs. The unit of measurement for load is LBF, or pound-force. Pound-force is often discussed in terms of kips, as 1000 LBF is equal to one kip.

Please note that these findings are applicable only to the hardware fabricated and distributed by Nelson Treehouse and Supply. These numbers are useful guidelines, not guaranteed limits, for the weight-bearing capacity of Nelson Treehouse hardware—actual load capacities should be determined by a structural engineer. Improperly installed hardware can pose a significant risk to all parties involved. Use hardware at your own risk. Be in a Tree LLC and Nelson Treehouse and Supply disclaim and assume no liability.

These gravity test findings demonstrate that Nelson Treehouse TABs are immensely strong—their load-bearing capacity exceeded our own expectations, giving us a greater margin of safety when designing treehouses. For instance, it took over 50 kips for the HL TAB with a suspension system to fail the gravity test!

Due to natural variation in wood density across tree species, the load-bearing capacity ranges widely depending on the species of tree in which the TAB system is installed. As we expected going into the tests, TABs in the less-dense Western Red Cedar had a much lower working and peak load capacity than those in the Doug Fir. Testing across these two tree species allows us to use them as comparison points for other tree densities, and plan our hardware accordingly.

TAbs were also tested with cable backup systems – here, peak load was reached when the cable snapped.

TAbs were also tested with cable backup systems – here, peak load was reached when the cable snapped.

We’re so grateful to WSU for hosting us for such a fascinating and useful study—big thanks to all those at the CMEC!

Want to know more about the TAB? Check out our Hardware Highlight post, here.

To the trees!