Chapelle—the first of four rentable treehouses at Treehouse Utopia—is full of special details, from its pair of arched windows to elongated wainscoting along the walls of its central room. Our carpenters prefabricated most of the components for this riverside retreat in our shop in Washington State. These components were then packed in a truck and shipped to Texas for our onsite crew to assemble and customize.

Step into our carpentry shop to see what went into prefabricating Chapelle!

One of Chapelle’s most distinctive features is its pair of arched, Gothic windows that flank its east- and west-facing sides. Our prefab crew framed the walls for these windows, cutting out the square spaces and leaving the plywood across the arched sections. This enabled the onsite crew to cut the arch to perfectly fit the window, accounting for any slight divergences from its model speculations.

The tall, arched windows in the completed treehouse allude to the chapel theme and make great use of the soaring space between the two host cypress trees.

The prefab crew also cut all the rafters, adding custom detailing to the soffits.

To account for planned variation in the Chapelle roof pitch and extent of its rafter overhang, our prefab crew adjusted the length of the detailing per rafter – this way, all the soffits look consistent on the completed structure.

The detailing on the soffits adds a special touch to the roofline on the finished treehouse.

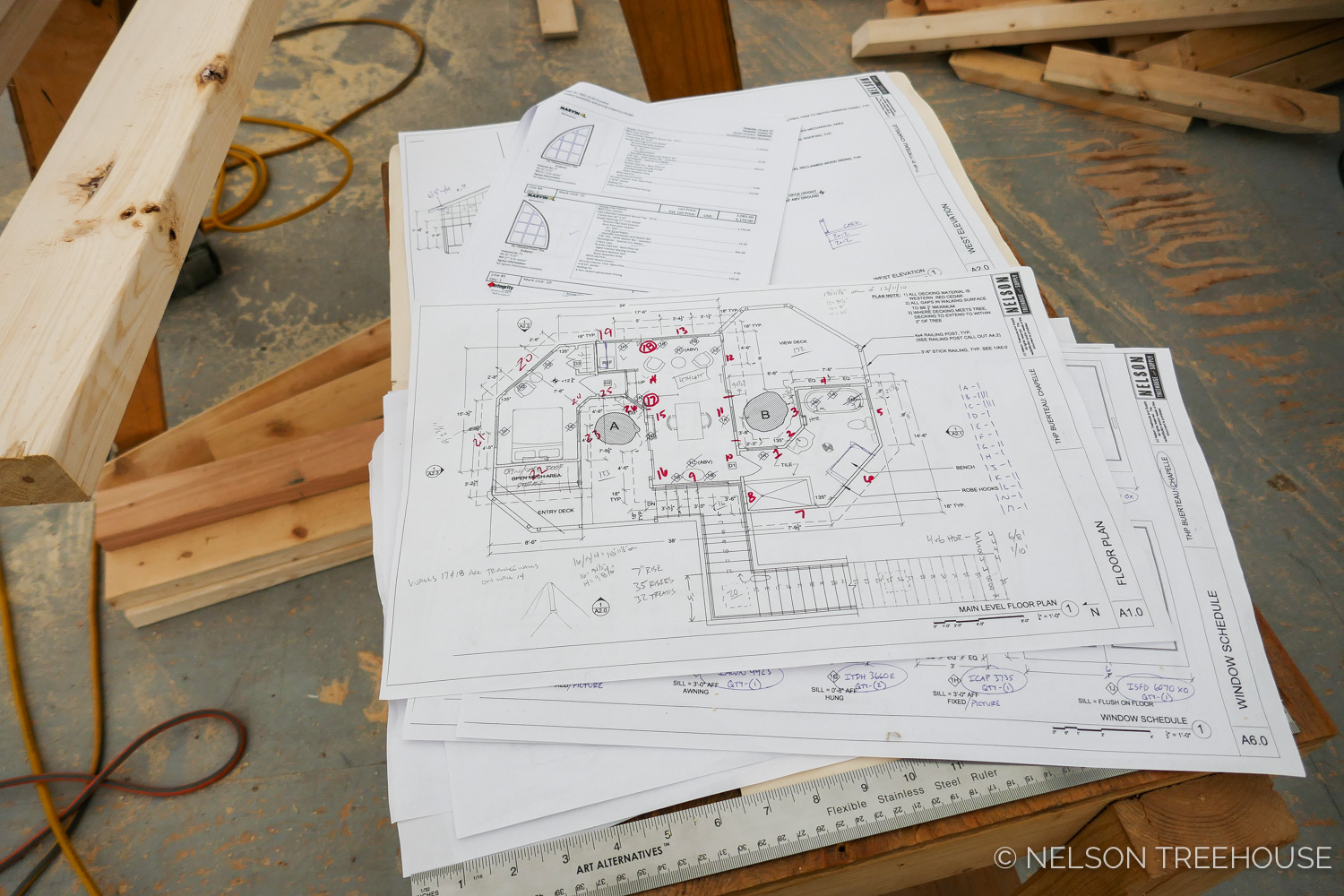

The red numbers on these shop drawings connect the prefabricated walls to onsite assembly. The prefab crew carefully labels each component so that the onsite crew can piece them together like a giant puzzle. You might be able to spot the numbers on the walls in the following photos.

Wall #5 was bound for one side of Chapelle’s bathroom. In an alternate method from the way they handled the Gothic windows, the prefab crew cut out the space for the stained glass window that would eventually fill this wall, leaving it up to the onsite crew to frame in the blank space to fit the glass.

With its sloped top and privacy window, wall #4 stands behind the yellow bathtub in the completed treehouse. You can learn how to frame a rake wall like this in our tutorial video below, starring our prefab shop wizard Griffin!

Here, you can see wall #4 (directly behind the tub) and wall #5 (with the stained glass on the right side of the tub) in their completed context.

Wall #7 encloses one side of the shower in the finished Chapelle bathroom. Our crew added the blocks at the bottom of this wall in an effort to provide an extra surface on which the onsite crew could attach the pan and/or protective membrane for the shower bed.

As it turned out, this well-intentioned effort was actually counterproductive as the onsite crew found it difficult to reach behind these blocks when securing the walls to the floor. This is a great example of the iterative process between prefab and onsite crews, as they experiment and collaborate to determine what works best for both parties.

On wall #9, you can see the framing structure behind the arched window for the front side of Chapelle.

A rare photo of prefab crew member Ian in his natural habitat.

Walls #24 and #25 include blocking up to five feet for an unusually tall chair rail. Our designers added this five-foot-high chair rail to match the look of the tall, vaulted ceilings.

Here, you can see the high chair rail and vertical paneling that runs along the walls of the main space. This and other design features in the main room—including the expansive window, exposed rafter ties, and built-in shelving—pull the eye upward, creating a grand, chapel-like experience.

The crew cut reclaimed Doug fir for car decking flooring.

Our crew member Rolf concocted this innovative setup to blow sawdust off the router while he cut cedar for tongue-and-groove paneling. On the days when Rolf needed to cut the cedar, the shaper (the tool he would normally use for this task) was being used for another job. This constraint led to the genesis of this unconventional (though highly creative and totally functional!) setup,

The resultant cedar from Rolf’s creative routing station.

When it was time to pack the truck with all the prefabricated components, the crew had to find a creative method to lift four prodigious steel yokes that would go to support Chapelle’s platform. Each of the four yokes weigh over 1300 pounds!

Ultimately, the crew came up with the incredibly original idea of using 2×4’s for leverage to pack the steel yokes. Hey, it worked!

Here, you can see the immense steel hardware installed onsite.

We hope you’ve enjoyed taking a look behind the scenes at the prefab process for Chapelle! Stay tuned as we continue to post exciting updates on the progress of Treehouse Utopia in the coming months

You can take our photo tour of the completed Chapelle here.

And click here to find out more about the plans for Treehouse Utopia.