Take a peek behind the build of our biggest treehouse yet in the rolling hills of Texas Hill Country.

This magnificent tree“mansion” is almost 2,400 square feet with 1,300 square feet of treetop deck space to enjoy the surrounding canopy of cypress trees. Our wonderful clients will call this their primary home which makes this tree-mendous treehouse that much more unique. The spacious one level home includes a great room with a wood burning fireplace, full kitchen, guest bedroom and bathroom, screened porch, mudroom and last but not least, the master suite including the bedroom, custom walk-in closet, bathroom and an outdoor hot tub off the bathroom deck.

Photo by Scott Atkins on the site visit

Photo by Scott Atkins on the site visit

The trees dictate every build. It may sound cheesy but we always say, “listen to the trees”. They’ll tell you where the treehouse belongs. Pete did the initial site visit and drew up a sketch of a pretty big treehouse for our wonderful clients. As the process went on, the layout evolved and became even larger, making this our biggest build yet!

The site alone is a whimsical slice of paradise where you’ll encounter exotic wildlife roaming the hundreds of acres.

Nine beautiful bald cypress trees support this grand treehouse over a meandering and magical creek.

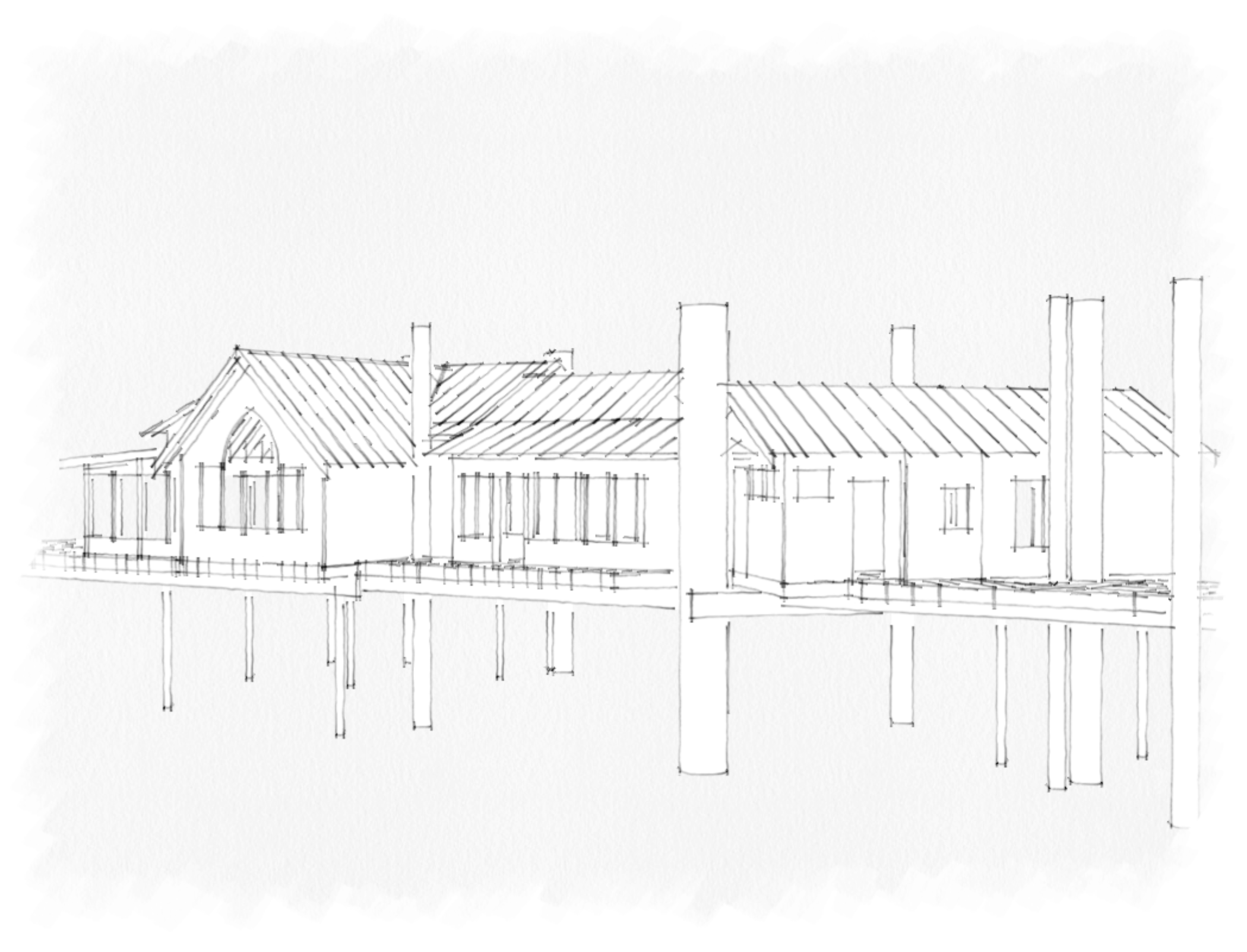

Bandera Treehouse Sketch by Scott Atkins

Bandera Treehouse Sketch by Scott Atkins

Built about 17 feet off the ground, supported by 9 soaring cypress trees and 14 posts, this grand treehouse requires our Treehouse Masters tested and approved Heavy Limb Hardware. We used 14 burly HL TAB’s (treehouse attachment bolts) and whole lot of engineering wizardry support this behemoth build.

A few fun facts for our fellow carpenter geeks:

Heavy Limb Metal Jacket

Heavy Limb Metal Jacket

Treehouse walls in the prefab shop waiting to be shipped

Treehouse walls in the prefab shop waiting to be shipped

Up next, Ian, Rolf & Griffin spent the summer expertly building walls and cutting rafters here in our prefab shop in Fall City, Washington. Once the walls and rafters are ready, they pack ’em up and ship them all the way to Texas to be puzzle pieced together. Prefabing parts of the treehouse in the shop, helps the onsite build go quicker and more efficiently!

Rolf working on the great room wall at the prefab shop.

Rolf working on the great room wall at the prefab shop.

The great room wall up onsite.

The great room wall up onsite.

The crew from left to right: Frank Belo, Kevin Keppler, Jake McCauley, Justin Kennedy and Michael Hegarty

The crew from left to right: Frank Belo, Kevin Keppler, Jake McCauley, Justin Kennedy and Michael Hegarty

Michael and Jake installing Marvin windows on the great room wall.

Lead Carpenter, Kevin cutting framing for the great room fireplace.

Fireplace right in the middle of the back wall with the full kitchen to the right.

Photo by Justin Kennedy

Photo by Justin Kennedy

View out of the gothic windows in the kitchen.

View out of the gothic windows in the kitchen.

kitchen ceiling

kitchen ceiling

These eye catching roof pitches were one of the hardest design challenges for Scott Atkins.

Screened porch off the great room with a connected radius deck.

Photo by Justin Kennedy

Photo by Justin Kennedy

Radius western red cedar deck outside the screened porch.

Guest bedroom with bathroom on the left, hallway down to the master suite and mud room on the right.

Master bedroom with almost 170 degree view of the surrounding cypress trees. Step through the sliding doors onto a private deck.

The layer beneath the treehouse is scaffolding for the crew to have easier access while working on the treehouse.

Our rockstar of a crew has been putting in their heart and soul into this prodigious build. We can’t wait to show you the complete treehouse in a few months!

In the meantime, take a virtual interior tour with our lead carpenter, Kevin Keppler:

View this post on Instagram